Toilet Seats Adjustable Universal Hinges

Basic Info.

| Model NO. | SDJ57795 |

| HS Code | 4016939000 |

| Production Capacity | 500000PCS/Month |

Product Description

Toilet seat hinge bolts

We are a manufacture mainly specialize in producing toilet hinge bolts, oil seal, customized rubber products.The materials are available in SILICONE, VITON, EPDM, NBR, HNBR, SBR, CR and so on. We have thousands of available O-ring moulds in stock and sample is free from our stock. We can also open new moulds as customers' drawings or physical sample for standard or non-standard O rings and other rubber parts.

Product Specification

1.Material | NBR 70+ stainless steel |

2.Color | Black |

3.Size | ABS plastic washer size: 33mm Rubber expanding fixing length 40mm Screw size: M6 x 50mm (length) Stainless steel washer size : 16mm |

4.Usage | Fits for most standdard toilet seat |

5.Packing details | 100 sets/bag, 500 sets/carton |

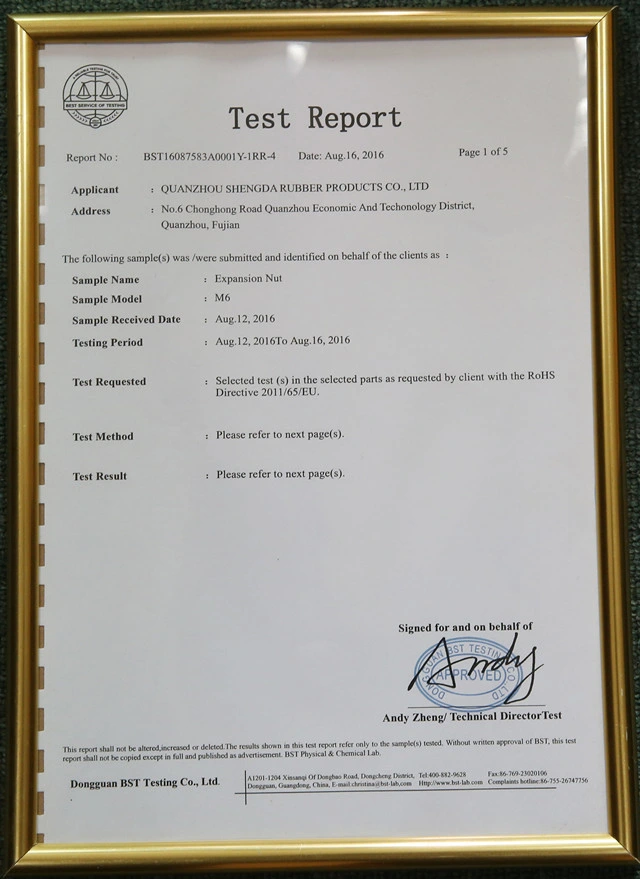

| 6.Certificate | RoHS |

| 7.Sample | Sample is free from stock |

| 8.MOQ | 100 pcs Toilet seat hinge bolt |

Packaging & Shipping

All OUR TOILET SEAT HINGE BOLT will be packed well before shipping. Normally, they will be shipped by sea, by air or by express according to the weight, the quantity, or as the customers' requirements.

Delivery Time: 2-7 days for samples

· 3-15 days for mass production

Our Services

Our Advantages:

1. more than 10 years factory experience at rubber manufacturing.

2. 2-7 days fast sample delivery time.

3. Audited by SGS and Alibaba, OEM,ODM service are available.

4. 3 years of Alibaba top gold supplier, We always put quality products as a primary objective

5. We accept sample order, trial order, mix order.

Certificate:

Company Information

We are majored in offering all kinds of rubber oil seals, O rings, gasket, washer, daily rubber using products for about 13 years in China.Our products have exported to many countries, main market are: North America, South America, Europe, Asia and Africa.

Shengda Rubber technical team can help with prototyping and planning largest volume production runs finding the best customised solution in the most cost-effective manner.

Once that the design has been agreed and the rubber specified, our craftsmen in the tool department manufacture a steel prototype mould by computer numerical control machines (CNC) and by electrical discharge machines (EDM).

We can provide prototype samples with the same specifications of the production parts within 10 to 20 working days depending on the complexity of the rubber component. Your design engineers can evaluate the products using production grade tooling and comparing various materials and hardness.

1. How to choose the material?

Not the expensive is the best, each material has its advantage, according to your requirements and the work environment of the rubber parts, choosing the best material.

2. Can I have my own design?

We are also getting into custom molded parts. We can make anything that will fit into any one of our mold presses. If you think that you have a product that can be made, send us an email and we can communicate back and forth to try and figure something out. We are always looking for something new to try.